View More

View More

View More

View More

View More

View More

View More

View More

Years Of Experience

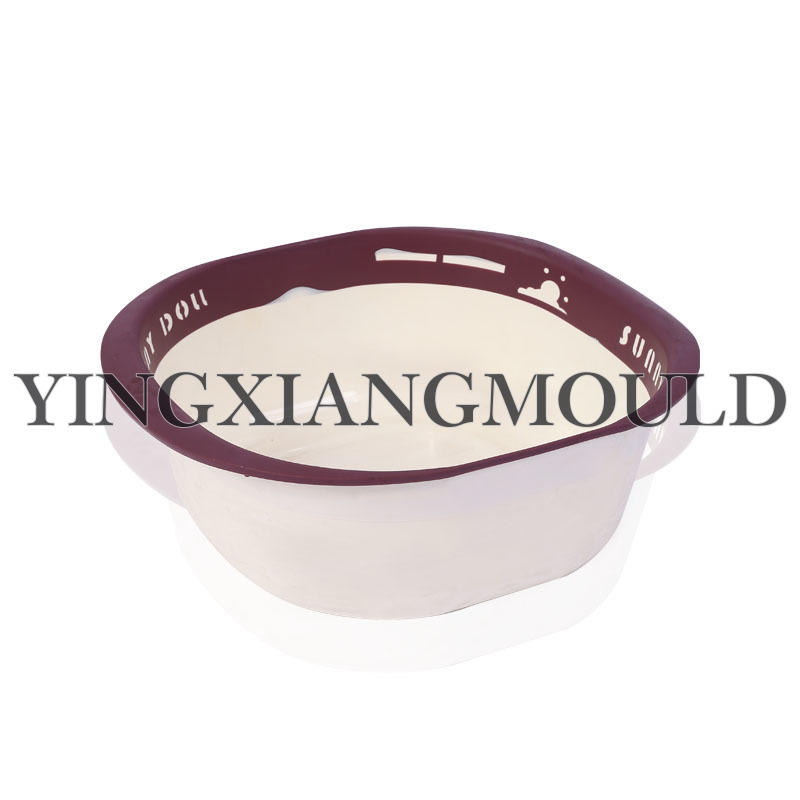

Boch Plastic Mould is China Plastic Trash Can Mould Manufactures and Custom Plastic Wash Basin Mould Factory. Our company is equipped with high-tech equipment and first-class CAD/CAE/CAM system. We have experienced technicians who strictly maintain and operate every process of production. We always adhere to the concept of lean manufacturing, long-life molds and on-time delivery to provide our customers with excellent quality, superior service, profitable growth and a complete mold solution. Recommended Products. We mainly produce crate finishing box molds, tray molds and daily household products molds, etc.

How Do You Store A Washbasin Mould When It's Not In Use?

When a washbasin mould is not in use, it should be properly stored to prevent damage and maintain its quality. Here are some general guidelines for storing a washbasin mould:

(1)Clean the mould thoroughly: Before storing the mould, make sure to clean it thoroughly to remove any debris, dust, or residue from the manufacturing process.

(2)Store the mould in a dry and cool place: The mould should be stored in a dry and cool place, away from direct sunlight and moisture. Avoid storing the mould in areas with high humidity or extreme temperatures.

(3)Keep the mould covered: Cover the mould with a protective covering, such as plastic wrap or cloth, to prevent dust or other debris from settling on the mould.

(4)Store the mould in a level position: The mould should be stored in a level position to prevent warping or distortion.

(5)Check the mould regularly: Periodically check the mould during storage to ensure that it is in good condition and has not been damaged.

What Is The Most Important Consideration When Selecting A Plastic Washbasin Mould?

The most important consideration when selecting a washbasin mould is to ensure that it is designed and manufactured to meet the specific requirements of the production process and the desired final product. Here are some factors to consider when selecting a washbasin mould:

(1)Material compatibility: The mould material should be compatible with the plastic resin used in the manufacturing process. The mould should be designed to withstand the high temperatures and pressure of the injection moulding process.

(2)mould design: The mould design should be optimized for the specific washbasin product to ensure consistent quality and performance. Factors such as the size, shape, and surface finish of the washbasin must be taken into account during mould design.

(3)Production volume: The mould should be designed and manufactured to meet the required production volume. For high-volume production, a mould with multiple cavities may be necessary to increase production efficiency.

(4)Maintenance and repair: The mould should be designed for easy maintenance and repair to minimize downtime and reduce production costs.

(5)Cost: The cost of the mould should be considered in relation to the expected production volume and the desired quality of the final product.